Call: 08045478270

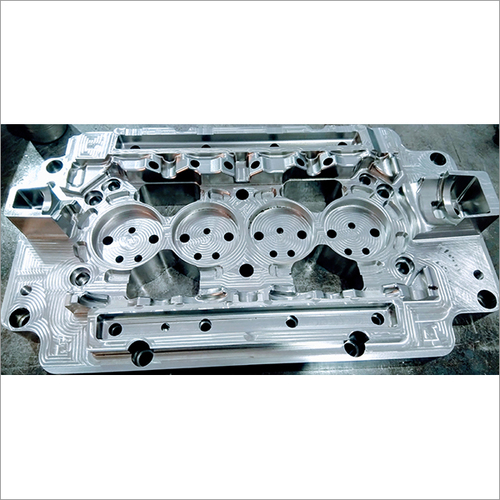

पà¥à¤¡à¥à¤¸à¥ मà¥à¤²à¥à¤¡

Price 100000.00 आईएनआर/ Set

MOQ : 1 Set

पà¥à¤¡à¥à¤¸à¥ मà¥à¤²à¥à¤¡ Specification

- लाइफ स्पैन

- Up to 1 million shots

- कोर मटेरियल

- Tungsten Carbide

- सहनशीलता

- ±0.01 mm

- काम करने की प्रक्रिया

- मोल्ड बेस

- Stainless Steel

- मटेरियल

- शेपिंग मोड

- पंच डाइस

- Removable Punch Dies

- डाई हेड

- Multi-cavity Die Head

- Customisation

- Available as per drawing/spec

- Heat Treatment

- Vacuum Heat Treated

- Size Range

- Customised as required

- Mould Cavity

- Single and Multi Cavity options

- Surface Finish

- Mirror Polished

- Application

- Wire Drawing, Cutting Tools, Mining

- Hardness

- HRC 58-62

पà¥à¤¡à¥à¤¸à¥ मà¥à¤²à¥à¤¡ Trade Information

- Minimum Order Quantity

- 1 Set

- आपूर्ति की क्षमता

- 8000 प्रति दिन

- डिलीवरी का समय

- 10 दिन

About पà¥à¤¡à¥à¤¸à¥ मà¥à¤²à¥à¤¡

Experience incomparable efficiency with our PDC Mould, crafted for those who demand peerless performance in wire drawing, cutting tools, and mining applications. Trending for its prodigious durability, each mould features mirror-polished surfaces, single or multi-cavity options, and is engineered from robust tungsten carbide with polycrystalline diamond. Vacuum heat treatment and stainless steel mould bases guarantee longevityup to 1 million shots at 0.01 mm tolerance. Order yours at a special rate and customise by drawing or specification for truly unique results from a leading manufacturer in India.

Versatile Uses and Distinct Advantages of PDC Moulds

Our PDC Moulds excel in diverse applications, including wire drawing, advanced metal forming, and cutting tools. Their usage type spans precision industrial tasks where superior hardness and wear resistance are critical. With the advantage of removable punch dies and multi-cavity options, these moulds deliver extended life, high output, and minimal maintenancemaking them an ideal investment for demanding manufacturing and mining environments.

Reliable Supply, Prompt Delivery, and Competitive Pricing

We maintain a prodigious supply ability, fulfilling bulk or customised orders efficiently. Anticipate swift delivery within agreed timeframes, with flexible payment terms for a seamless exchange. Our moulds are listed at the most competitive prices, ensuring you access the lowest possible cost without compromising on quality or service. Discover peerless value in every transaction, backed by dedicated support from Indias premier PDC mould supplier.

Versatile Uses and Distinct Advantages of PDC Moulds

Our PDC Moulds excel in diverse applications, including wire drawing, advanced metal forming, and cutting tools. Their usage type spans precision industrial tasks where superior hardness and wear resistance are critical. With the advantage of removable punch dies and multi-cavity options, these moulds deliver extended life, high output, and minimal maintenancemaking them an ideal investment for demanding manufacturing and mining environments.

Reliable Supply, Prompt Delivery, and Competitive Pricing

We maintain a prodigious supply ability, fulfilling bulk or customised orders efficiently. Anticipate swift delivery within agreed timeframes, with flexible payment terms for a seamless exchange. Our moulds are listed at the most competitive prices, ensuring you access the lowest possible cost without compromising on quality or service. Discover peerless value in every transaction, backed by dedicated support from Indias premier PDC mould supplier.

FAQs of PDC Mould:

Q: How can PDC Moulds be customised according to my project requirements?

A: PDC Moulds are customised as per your drawing or specification, allowing precise configuration of cavity numbers, sizes, and surface finishes. Simply share your technical requirements, and well deliver a mould tailored for your application.Q: What benefits does the mirror-polished surface finish provide?

A: The mirror-polished finish ensures smoother material flow, reduces friction, and extends the mould lifespan, resulting in superior output quality and lower maintenance needs.Q: When is it advantageous to opt for a multi-cavity mould design?

A: Multi-cavity moulds are ideal when you require higher production rates, consistent part quality, and efficient material utilisation. Their design is particularly beneficial when manufacturing is frequent and in large quantities.Q: Where can these PDC Moulds be utilised besides wire drawing?

A: Apart from wire drawing, our PDC Moulds are widely used in cutting tools manufacturing, mining operations, advanced forming applications, and any industry that demands high precision and enduring tool life.Q: What is the supply process after placing an order for PDC Moulds?

A: Once your order is confirmed and specifications finalised, production begins with precision machining and vacuum heat treatment. We ensure timely delivery and flexible payment arrangements to streamline the procurement experience.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in डाई और सांचे Category

डाई कास्टिंग मोल्ड

वज़न : किलोग्राम (kg)

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

उपयोग : Automotive, Electronics

साइज : Customizable

वारंटी : 1 Year

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें